The post Fixing systems for the entrance of the Heineken Experience appeared first on Walraven United States of America.

]]>

Amsterdam I The Netherlands

Background

Heineken, the globally known beer brand, wanted a spectacular entrance to the Heineken Experience Center in Amsterdam. To be able to create this, the existing building was renovated, and the old stables were turned into a large welcome area. The contractor company Salverda was responsible for this major renovation project. Architect Ideal Projects designed a plan to give a spectacular feeling to the entrance: thousands of Heineken bottles glittering towards visitors from the ceiling. This is where Walraven came in. Salverda asked Walraven, as an expert in fixing systems, to come up with a solution for fixing 11,000 Heineken bottles to the lobby ceiling. Salverda was a great partner during this project, with whom we collaborated in the phases of decision-making and testing.

Requirements

Fixing 11,000 Heineken bottles to the ceiling asked for a tailor-made solution.

Solution

Walraven invented, produced, and partly prefabricated a customized solution consisting of two parts. The first part holds the bottle, and the second part allows the bottles to be attached to the ceiling.

Rubber insert

For the first part, we developed and produced a rubber insert together with Jefleks, our rubber factory in Turkey. The rubber insert had to meet several criteria: the perfect shape, the right hardness of the rubber, the best way to hold the bottle, and of course, ease to assemble. The end result was a rubber insert placed in the neck of the bottle and tightened with a bolt connection. It is tightened longitudinally, which causes it to expand in width and thus secures itself in the neck of the bottle.

Walraven Rapidrail® fixing rail and Walraven Hammerfix

For the second part of the solution, Walraven designed and produced a customized Walraven Rapidrail® fixing rail. The lobby’s walls and ceiling have a double-wall structure and a bottom layer with cut-outs for the bottles. By using the customized Walraven Rapidrail® fixing rail in combination with the Walraven Hammerfix, it was possible to place the bottles in long rows onto the rails. An assembly-friendly solution but as well multifunctional because the rails were also used for fixing the light points.

The post Fixing systems for the entrance of the Heineken Experience appeared first on Walraven United States of America.

]]>The post High quality corrosion protection suitable for food industry appeared first on Walraven United States of America.

]]> A Danish chocolate and confectionery manufacturer invested in a modern production facility in Nowa Sól, Poland. The new plant will create about 130 new jobs for local residents and the Toms Group will systematically increase its activities in the city and employ more and more workers. In terms of the supply chain, Nowa Sól is an ideal location for the Toms Group. “2018 was the year where we took a giant leap in the transformation of our supply chain platform and initiated the construction of a new manufacturing plant in Nowa Sól,” said Carsten Lyngsø Thomsen, CEO of the Toms Group, 2018.

A Danish chocolate and confectionery manufacturer invested in a modern production facility in Nowa Sól, Poland. The new plant will create about 130 new jobs for local residents and the Toms Group will systematically increase its activities in the city and employ more and more workers. In terms of the supply chain, Nowa Sól is an ideal location for the Toms Group. “2018 was the year where we took a giant leap in the transformation of our supply chain platform and initiated the construction of a new manufacturing plant in Nowa Sól,” said Carsten Lyngsø Thomsen, CEO of the Toms Group, 2018.

The PM Group was appointed supervisor of the project. Their involvement began in 2016 with site selection, concept design development and site master-planning. It continued through basic and detailed design, procurement, construction management, supervision of the architect, commissioning and start-up assistance.

The project was recognized with a regional award from the National Labor Inspectorate for the high value placed on safety.

The challenge

As you walk through a typical food processing plant, you can see equipment constructed of a myriad of materials, including carbon steel, aluminum, stainless steel and plastics. Corrosion can be an enemy of many of those materials. Because of the quality of food requirements, purity and sanitation standards require excellent corrosion resistance in the entire production area. These food quality requirements lead most plants to select stainless steel as a material of choice.

The Solution

Our technical engineers worked closely with the main contractor and the installation subcontractor throughout the project to develop an effective and high quality support solution for the diverse pipe installations. Due to the corrosive environment around these installations, special consideration had to be given to the surface protection of the components. At first only Stainless Steel A2 or A4 was allowed to be used. We convinced the investor and supervisor to recommend Walraven’s BIS UltraProtect® 1000 fixing system solution. This system consists of products treated with the special Walraven BIS UltraProtect® 1000 coating. It withstands up to 1,000 hours salt spray test (according to ISO 9227), ensuring the best corrosion protection, making it suitable for industrial food environments.

Our technical engineers worked closely with the main contractor and the installation subcontractor throughout the project to develop an effective and high quality support solution for the diverse pipe installations. Due to the corrosive environment around these installations, special consideration had to be given to the surface protection of the components. At first only Stainless Steel A2 or A4 was allowed to be used. We convinced the investor and supervisor to recommend Walraven’s BIS UltraProtect® 1000 fixing system solution. This system consists of products treated with the special Walraven BIS UltraProtect® 1000 coating. It withstands up to 1,000 hours salt spray test (according to ISO 9227), ensuring the best corrosion protection, making it suitable for industrial food environments.

In addition to the topic of corrosion protection, our technical engineers also had to take the pipe expansion and contraction into account. If the behavior of the pipe, due to temperature differences, is not properly accounted for when installing the pipework, the movement of the pipe will damage the pipe support systems over time. Expansion devices were installed to allow for the linear thermal movement.

In addition to the topic of corrosion protection, our technical engineers also had to take the pipe expansion and contraction into account. If the behavior of the pipe, due to temperature differences, is not properly accounted for when installing the pipework, the movement of the pipe will damage the pipe support systems over time. Expansion devices were installed to allow for the linear thermal movement.

Our engineers were technically involved in the calculations and drawings and visited the construction site several times.

Type of installations:

Type of installations:

- Heating

- Cooling

- Steam

- Ventilation

Products used:

- Walraven Heavy Duty Clamps (BUP1000)

- Walraven BISOFIX® E19

- Walraven BISOFIX® PIR

- Walraven Threaded Rods (BUP1000)

- Walraven Expansion devices (BUP1000)

- Walraven RapidStrut® channel (BUP1000)

- Walraven RapidStrut® channel accessories (BUP1000)

- Walraven Strut ‘Heavy Duty’ Beam Clamp (BUP1000)

How can we help you?

If you need a flexible, effective and easy to install solution for supporting your pipework in highly corrosive environments, our Walraven Technical Engineers can provide a comprehensive project support service to help you design and deliver an effective solution. Call your Walraven Regional Sales Manager (RSM) and let us find a solution for your installation.

The post High quality corrosion protection suitable for food industry appeared first on Walraven United States of America.

]]>The post Walraven provide smart solution for stairwell installation appeared first on Walraven United States of America.

]]>The installation problem

The entire length of the riser pipes needed to be supported. However, neither the pipework or its support could intrude on the actual stairwell. The solution required an original, bespoke design.

The solution

The Walraven UK Technical Team worked closely with the client to design and calculate a bespoke vertical box frame. This bespoke design was constructed on site with the added benefit of on site consultation from our team. The frame was bolted to the floor and landings, allowing the frame to support the pipes without any intrusion on the stairwell.

Products Used

- Walraven RapidStrut® channel System

- Walraven Hammerfix

- Walraven 2s Clamp

- Walraven BIS PushStrut

- Walraven Connectors and bolts

How can we help you?

If you have a challenging or unusual installation we may be able to help. Contact your Walraven Regional Sales Manager (RSM) to find out more about the solutions Walraven could offer you.

Find my RSM Read more case studies More about RapidStrut® channel

The post Walraven provide smart solution for stairwell installation appeared first on Walraven United States of America.

]]>The post Heavy pipe support system for rooftops appeared first on Walraven United States of America.

]]> The M&E contractor working on the Thames Tower high rise office block in Reading required advice about how to effectively support the rooftop services coming from the plant room. Walraven were approached to provide a technical design solution which was taken forward and implemented with great success.

The M&E contractor working on the Thames Tower high rise office block in Reading required advice about how to effectively support the rooftop services coming from the plant room. Walraven were approached to provide a technical design solution which was taken forward and implemented with great success.

The Problem

This was a rooftop installation project to support very heavy pipework. The solution had to take into account several factors:

- It had to be suitable for outdoor use

- Take into account the thermal expansion of the pipework it would be supporting

- Allow for a non-penetrative roof design

- Be easy to install in a confined space

The Solution

Our technical support team provided drawings and load calculations to recommend a combination of Walraven installation systems. This was followed up with a toolbox talk on-site.

Our technical support team provided drawings and load calculations to recommend a combination of Walraven installation systems. This was followed up with a toolbox talk on-site.

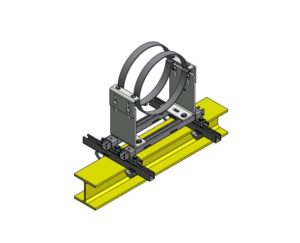

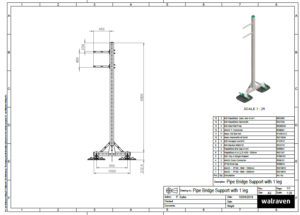

The Walraven Maxx frame system is perfectly suited to supporting heavy pipework and is suitable for outdoor use. Used in combination with our expansion guides, the pipes would be effectively supported whilst allowing for thermal expansion. To provide a non-penetrative rooftop attachment, our Walraven Yeti® rooftop support feet were used.

The Walraven Maxx frame is a flexible, heavy rail system that is safe, secure and corrosion resistant. It is suitable for many applications and is quick and easy to install without the need for on-site fabrication or welding – perfect for confined spaces.

The Walraven Maxx frame is a flexible, heavy rail system that is safe, secure and corrosion resistant. It is suitable for many applications and is quick and easy to install without the need for on-site fabrication or welding – perfect for confined spaces.

How can we help you?

Would you like to find out more about how the Walraven Maxx heavy rail system could benefit your projects? Call your Walraven Regional Sales Manager (RSM) to find out how we can help.

Find my RSM Read more case studies

The post Heavy pipe support system for rooftops appeared first on Walraven United States of America.

]]>The post Effective fire stop solution for expanding pipework appeared first on Walraven United States of America.

]]>The problem

Large pipework in the basement required supports allowing for expansion, as well as fire stopping of the pipe penetrations through firewalls to ensure safety of fire escape routes. There were a number of different substrates and arrangements that required solutions, along with the added issue of pipe expansion and contraction. If pipe expansion and contraction is not correctly considered when installing a fire stop, the movement of the pipe could render the fire stop ineffective over time.

The Fire Stop Solution

Walraven’s range of fixing points and slide guides were ideal for fixing the large pipework system, whilst allowing it to expand and contract. The Walraven Pacifyre® MKII Fire Sleeve was recommended for fire stopping. It is unique in that it allows pipes to expand and contract without compromising the effectiveness of the fire stopping – unlike fire collars which hold pipework static, preventing the pipe from expanding freely, potentially resulting in failure. Walraven provided technical advice, design solutions and on site support for this project.

How can we help you?

Would you like specialist advice about effective passive fire protection for expanding pipework? Call your Walraven Regional Sales Manager (RSM) to find out how we can help with a fire stop solution.

Find my RSM

The post Effective fire stop solution for expanding pipework appeared first on Walraven United States of America.

]]>The post Perfect installation in a small space appeared first on Walraven United States of America.

]]> but Walraven was able to complete the job professionally and efficiently.

but Walraven was able to complete the job professionally and efficiently.

The Problem

There was very little space to work, for which a solution had to be found. Properly functioning ventilation ducts had to be installed. But they could not be attached to the floor or walls. That’s when Avantor asked Walraven for help.

Walraven’s Solution

Our normal solutions, Walraven Yeti and Walraven Urus, could not be used here, therefore we opted for our heaviest system: Walraven Maxx profile. With this system, we installed the big ventilation ducts above each other in layers. These were attached to the main substructure of the building.

Since we produce the materials used, we could deliver everything to the location at Avantor within 48 hours. This saved the customer a lot of time. From estimating to execution, we provided all the information and performed all the work.

We Are Here To Help You

Do you also have a considerable challenge with the installation of your project? Our staff will gladly help you with sound advice and choosing the right products. Please call us, 800-610-5056, or email us at: [email protected].

The post Perfect installation in a small space appeared first on Walraven United States of America.

]]>The post Installation Time Reduced By 150 Hours With Walraven RapidRail® fixing rail appeared first on Walraven United States of America.

]]> The Heatcare company provides luxury care homes for the elderly in south England, and have worked with Walraven for many years. They are one of the UK’s most highly-respected and accredited contractors working in the care industry, building a reputation for high quality design, delivery and engineering expertise. Heatcare is committed to providing technical excellence and quality workmanship.

The Heatcare company provides luxury care homes for the elderly in south England, and have worked with Walraven for many years. They are one of the UK’s most highly-respected and accredited contractors working in the care industry, building a reputation for high quality design, delivery and engineering expertise. Heatcare is committed to providing technical excellence and quality workmanship.

The Ultimate Goal

Heatcare asked us to work with them to find a way to speed up the installation process for the mechanical systems throughout their care home projects without sacrificing quality.

The Perfect Plan

We recommended our Walraven RapidRail® fixing rail system as the fast and flexible solution. This included our Walraven BISMAT 5000 clamps which are perfectly suited to plastic pipe systems where expansion is expected.

With the added benefit of pre-fabrication in our own factory, we could deliver pre-assembled units for immediate installation.

Collaboration is important on these kinds of projects early in the planning process. Accurate information is critical to make sure that the pre-fabricated systems fit perfectly.

At a care home location in London, the entire ground floor was installed in 1.5 days. Normally this would take 1 to 2 weeks. Gavin Hayes, Project Manager at Heatcare commented:

“Walraven RapidRail® fixing rail is our preferred pipe support system for installation

projects.  It’s a great quality product that is fast and easy to install. We have saved over 150 hours installation time using this product range. We have also used Walraven’s design, take-off and pre-fab services which helped the project run very smoothly. We would highly recommend Walraven products and services”.

It’s a great quality product that is fast and easy to install. We have saved over 150 hours installation time using this product range. We have also used Walraven’s design, take-off and pre-fab services which helped the project run very smoothly. We would highly recommend Walraven products and services”.

Download our Walraven RapidRail® fixing rail brochure here

We Are Here To Help

Let us help you reduce installation time on your installation projects. Simply call our team to find out how we can help you with technical issues and choosing the right products for your needs. Please contact us at 800-610-5056 or [email protected].

The post Installation Time Reduced By 150 Hours With Walraven RapidRail® fixing rail appeared first on Walraven United States of America.

]]>