Incorrect installation is the leading cause of problems encountered with heavy duty anchors. Poor installation may lead to a reduction of safety margins that are built into the anchor design process, a failure of the anchor during installation or during its service life. Some anchoring products are more sensitive to installation errors than others, but in any application, the full performance expected from an anchor can only be achieved if the correct installation process has been followed.

Incorrect installation is the leading cause of problems encountered with heavy duty anchors. Poor installation may lead to a reduction of safety margins that are built into the anchor design process, a failure of the anchor during installation or during its service life. Some anchoring products are more sensitive to installation errors than others, but in any application, the full performance expected from an anchor can only be achieved if the correct installation process has been followed.

All anchors should be installed in accordance with the manufacturer’s prescribed installation procedure, which is always documented in the European Technical Assessment of a given product. Therefore, the first step in making safe installations is to study and familiarise yourself with the official installation instructions and follow them.

One, sometimes overlooked aspect of the installation procedure, is the cleaning of a drilled hole. For mechanical anchors, cleaning the drilling dust out of the hole with a blow-out pump is generally sufficient. With the dust removed, it will not interfere with the anchor’s functioning mechanism and the anchor will have sufficient space in the hole to reach its intended embedment depth.

The hole cleaning procedure for chemical anchoring systems, however, is especially important. During the drilling, the drill bit compresses dust onto the surface area of the hole. Air generated by a blow-out pump or even compressed air is insufficient to dislocate the dust and remove it. If the dust is not removed, the injected resin will bond to the dust instead of the concrete itself, and this will result in a significant performance loss of the anchor. The hole should be cleaned with a sequence of blowing and brushing operations, which is always detailed in a product’s approvals or technical documentation. The brush should have a slightly larger diameter than the hole it will be used to clean. Avoid using nylon brushes, as their cleaning performance is generally low. Walraven recommends using hybrid brushes made of steel wire and natural bristle. If you are unsure what diameter or type of cleaning brush you should use, please feel free to contact our experts.

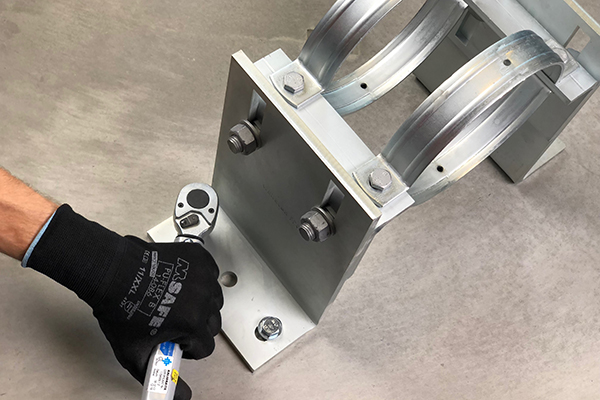

Apply too little torque on a torque-controlled anchor and it will not deliver it’s intended performance. Apply too much torque and you will risk over-stressing the anchor and thus also affecting its performance. If you over-torque a chemical anchor installation, you may break the chemical bond between the resin and the steel element. If you do not tighten a fixture sufficiently, the gradual relaxation of the nut may reduce clamping force induced and thus jeopardize its safety. Considering this, applying the correct amount of torque is always important.

With a few exceptions, like some hammer-in anchors, most heavy duty concrete anchors require controlled-torque either to be set correctly or for correct tightening of a fixture. Getting it wrong without using a torque-wrench is very easy and the risk for adversely affecting the anchor performance is high. At the same time, torque-wrenches are widely available and torque-related installation issues can be avoided by using them.

Products’ approvals and technical documentation will always specify the amount of torque required to complete the installation correctly. Mind the torque, and you will be one step closer to installing safe anchors!

Correct hole cleaning and application of torque are two important aspects of anchor installation. Before installing anchors, familiarize yourself with their installation procedure and ensure that you have the right tools and accessories to install and set them.

Do you want more information about our Heavy Duty Anchors? Or can we help you in determining which anchor is the best for your installation? Please feel free to contact us to discuss this with our experts. Our Walraven Technical Support Teams are always ready to help you with your project and provide advice on installation of anchors. Don’t hesitate to get in touch!