The post Safe Access to Trane Machines for Maintenance – Smart Prefabricated Installation at TLR Ridderkerk by Walraven, Trane & Utitech appeared first on Walraven International.

]]>Introduction

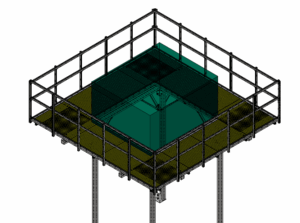

Through an innovative collaboration between Walraven, Trane and Utitech, the Trane machines on the roof of TLR Ridderkerk are now safely and efficiently accessible for maintenance. Thanks to digital engineering, prefabricated solutions, and intensive coordination, a service deck has been realised that meets the highest safety and sustainability standards, significantly facilitating the work of technicians and installers.

Challenge

TLR International Laboratories in Ridderkerk, specialists in food and animal feed analysis, faced a complex challenge: safely and efficiently managing and maintaining two large Trane CMAF multi-pipe units on the roof. The lightweight roof structure meant that traditional installation methods could not be applied. A temporary scaffold did not provide sufficient safety or flexibility, prompting TLR to seek a sustainable, future-proof solution.

Solution

In close collaboration, Trane, Walraven, and Utitech developed a bespoke service deck. Walraven brought digital innovation to the process by measuring the roof and existing situation with millimetre accuracy using a 3D scan (LiDAR). Based on this digital twin, a floating service deck was designed, which did not rest on the roof but on the existing steel structure. The design was presented in AR/VR to Trane and TLR so that all parties could assess the result in advance. The prefabricated approach, with Walraven RapidStrut® systems, handrails, and durable surface treatment (Walraven BIS UltraProtect 1000®), ensured a safe, efficient, and future-proof platform.

In close collaboration, Trane, Walraven, and Utitech developed a bespoke service deck. Walraven brought digital innovation to the process by measuring the roof and existing situation with millimetre accuracy using a 3D scan (LiDAR). Based on this digital twin, a floating service deck was designed, which did not rest on the roof but on the existing steel structure. The design was presented in AR/VR to Trane and TLR so that all parties could assess the result in advance. The prefabricated approach, with Walraven RapidStrut® systems, handrails, and durable surface treatment (Walraven BIS UltraProtect 1000®), ensured a safe, efficient, and future-proof platform.

Execution

Materials were delivered from Walraven Mijdrecht and placed on the roof by Utitech in segmented loads to prevent overloading. Installers received VR training and clear instructions in advance, enabling safe and swift installation. Drone footage documented the process for future training and communication. The collaboration was intensive and transparent, with continuous coordination and involvement from all parties. The project was completed within five working days, with strict quality controls and a focus on safety.

Testimonials (summary and connection)

Piet Haage (Trane): Emphasises the importance of safety and circularity. Trane sees the project as a market example, with the prefabricated approach and service deck contributing to a shorter lead time, higher safety and future-proof solutions. The collaboration is considered particularly good, with much professionalism and depth.

Read Piet’s testimonial

Willem van Rotterdam (Utitech): Appreciates the intensive collaboration and clear instructions provided in advance. The prefabricated configurations and the Walraven RapidStrut® rail system resulted in significant time savings and increased efficiency. Willem stresses that good cooperation between installers, suppliers and clients leads to lower failure costs and more value in the chain.

Read Willem’s testimonial

Lukas Buchsteiner (Advisory Bureau J Vriesema): Interview to follow, but Lukas is enthusiastic about the innovative approach and sees opportunities to apply this method more widely, for example, in hospitals.

Read Lukas’s testimonial

Collaboration & Innovation

This project demonstrates how progress arises through collaboration and shared innovation. Each party contributed its own expertise: Trane with sustainable cooling and heating solutions, Utitech with expert installation and logistics, and Walraven with digital engineering and prefabrication. Open communication and joint commitment resulted in a future-proof solution that can inspire similar projects in the sector.

The post Safe Access to Trane Machines for Maintenance – Smart Prefabricated Installation at TLR Ridderkerk by Walraven, Trane & Utitech appeared first on Walraven International.

]]>The post Walraven RapidRail® delivers fast and convenient pipework installation appeared first on Walraven International.

]]>London I UK

Rosario Heating Ltd is a domestic and commercial heating engineer based in London. When called to work on a prestigious property renovation in Notting Hill, Savio Rosario knew that Walraven RapidRail® would be his preferred solution for the extensive pipework installation throughout this large residential property.

Rosario Heating Ltd is a domestic and commercial heating engineer based in London. When called to work on a prestigious property renovation in Notting Hill, Savio Rosario knew that Walraven RapidRail® would be his preferred solution for the extensive pipework installation throughout this large residential property.

“We have been using Walraven RapidRail® for about 3 years now. We used to use standard 41×41 strut and fixings for our plant rooms and pipework but when we saw another installer using Walraven RapidRail®, we wanted to give it a try. The lightweight channel and fixings are so convenient, we find it much easier to fix to both ceilings and walls for horizontal and vertical pipe runs.”

The challenge: Extensive pipework installation throughout luxury 4-storey property

The luxury property was undergoing an extensive renovation including the construction of an extra basement living level, that would also house a heat pump plant room. Rosario Heating Ltd were contracted to install the plant room and pipework that needed to be extended throughout the property, on all levels to deliver an efficient heating solution.

The luxury property was undergoing an extensive renovation including the construction of an extra basement living level, that would also house a heat pump plant room. Rosario Heating Ltd were contracted to install the plant room and pipework that needed to be extended throughout the property, on all levels to deliver an efficient heating solution.

“This property required a huge amount of pipework to be installed from the plant room, along the ceilings and walls, and through risers to all levels. We knew that RapidRail® would be a great solution having used it on many installations before. Not only is it easy to use but it gives a very professional look, which is important to some clients.”

The solution: Pre-fabricate RapidRail® brackets on site for easy installation throughout

The way it was used on this project was mainly through the creation of pre-fabricated brackets on site. The installer measured and planned the bracket requirements for each section of the build, cut the channel to length and pre-assembled with end caps, Hammerfix and pipe clamps, before fixing to the ceiling (or wall).

The way it was used on this project was mainly through the creation of pre-fabricated brackets on site. The installer measured and planned the bracket requirements for each section of the build, cut the channel to length and pre-assembled with end caps, Hammerfix and pipe clamps, before fixing to the ceiling (or wall).

This means a run of brackets can be assembled, with all the clips lined up before fixing. Small adjustments can still be made when in place, if required, as the Hammerfix can simply slide before tightening.

“The Hammerfix slide nut with pre-cut lengths of stud is a real game changer for us. Saves all the time and hassle of cutting your own stud lengths for pipe clamps. Plus the adjustability before tightening just helps it all go smoother without having to take anything apart!”

Savio Rosario, Heating Engineer

The post Walraven RapidRail® delivers fast and convenient pipework installation appeared first on Walraven International.

]]>The post Walraven RapidRail® Rail Systems makes light work of ceiling hanging pipe supports appeared first on Walraven International.

]]> Chris Illingworth, a plumber, has started using Walraven RapidRail® Systems for his large domestic and light commercial installations, and recently found it particularly useful on a job for fabricating ceiling hanging trapeze frames.

Chris Illingworth, a plumber, has started using Walraven RapidRail® Systems for his large domestic and light commercial installations, and recently found it particularly useful on a job for fabricating ceiling hanging trapeze frames.

This installation was a large, new, ultra-modern house that a ground source heat pump would heat. Chris and his team were tasked with fitting out the plant room and installing all the pipework throughout the property for the heating system.

The Problem – Installing at height

This installation required ceiling-hanging pipe supports throughout the property. Usually, Chris and his team would have used a standard 41×41 strut channel to create trapeze frame supports for suspended pipework. However, the 41×41 strut is heavy, weighing around 2.5kg per metre and comes with basic fixings for attaching pipe clips. When installing overhead, this can become challenging due to the weight and the meticulous nature of using basic fixings. Chris decided to try Walraven RapidRail® Rail, which weighs less than 1kg per metre, to see if using a lighter channel with fully pre-assembled fixings would make a difference.

The Solution – Walraven RapidRail® Rail System

Walraven RapidRail® Rail 30×20 was used on this job for both the wall-mounted pipework and for fabricating trapeze frames to carry the pipes through the ceiling space. The trapeze frames were constructed using two Walraven RapidRail® Rail pieces with Walraven RapidRail® Slide Nuts to drop the threaded rod down and connect the two pieces of channel. Walraven Hammerfix Nuts with pre-cut stud were used to attach the pipe clips, quick and easy!

Walraven RapidRail® Rail 30×20 was used on this job for both the wall-mounted pipework and for fabricating trapeze frames to carry the pipes through the ceiling space. The trapeze frames were constructed using two Walraven RapidRail® Rail pieces with Walraven RapidRail® Slide Nuts to drop the threaded rod down and connect the two pieces of channel. Walraven Hammerfix Nuts with pre-cut stud were used to attach the pipe clips, quick and easy!

Chris commented, “Part of the reason for using Walraven RapidRail® Systems is the fact that it’s light and easy to use at height on the scaffolds whilst installing the framework. This, alongside the really easy Walraven Slide Nut and Hammerfix Connectors that just twist into the rail, really helped bring the installation time down from what we estimated it would be using the heavier 41×41 strut channel. The system really exceeded our expectations and made the installation at height much easier.”

The post Walraven RapidRail® Rail Systems makes light work of ceiling hanging pipe supports appeared first on Walraven International.

]]>The post Efficient, safe, and on time: how installer streamlined heavy equipment installation project appeared first on Walraven International.

]]>Milan I Italy

When a renewable energy specialist, RTS Srl, required two heavy-duty support frames with complex requirements, they turned to Walraven for technical support.

Challenge: Elevated installations with multiple design factors to consider

The requirements on this project were complex, involving elevated installations with considerations for loads, spatial constraints, wide spans, logistics and safety.

Traditional construction methods, such as welded steel frames, were considered but quickly proved impractical due to logistical constraints, installation complexity, and time limitations. The customer needed a flexible, engineered solution that could be delivered quickly, installed easily, and meet all structural and safety requirements.

Solution: Walraven Maxx System provides flexible, modular solution

There were two bespoke supports required for this project:

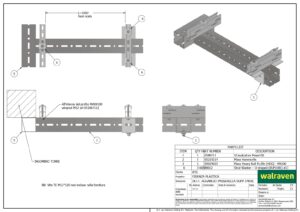

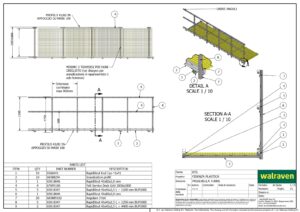

Support 1: High-level pipe bridge

The first installation required a dedicated metal frame to support piping installations above the HVAC units that were positioned on the ground. The structure needed to fit the space around the large HVAC unit which measured 9 metres long, 5 metres wide, and 3 metres high. Walraven provided a comprehensive design solution using a combination of Walraven Maxx 150 and Maxx 120. We delivered a robust and modular metal frame structure that met all technical and logistical requirements for this project, including addressing environmental factors such as wind and snow loads.

Support 2: Elevated support frame with walkway

The second part of the installation required the design of a support frame for a large HVAC unit weighing 3 tonnes and measuring 2×2 metres, which needed to be installed 3 metres above ground level, with a surrounding walkway for maintenance access. Our team proposed using a combination of Walraven Maxx profile for the load-bearing frame and Walraven RapidStrut® system to ensure precise management of pipes and cables. This combination offers a safe, stable, and easy-to-install solution.

Thanks to Walraven’s Channel systems and technical support, the customer was able to deliver both installations with confidence, ensuring structural integrity, safety, and ease of installation. By choosing Walraven, the customer benefited from having one trusted partner for all structural components, streamlining the project and ensuring a high-quality outcome.

The post Efficient, safe, and on time: how installer streamlined heavy equipment installation project appeared first on Walraven International.

]]>The post How to create a sea resistant fastening systems? appeared first on Walraven International.

]]>

Pier project

Haffkrug I Germany

Walraven was contacted very early in this project to help with the configuration and provide materials.

Challenge

A new 230-meter-long zigzag pier has been constructed in Haffkrug on the Baltic Sea. It features a modern design with a strong emphasis on sustainability. The challenge was to connect the event venue, designed as a ‘weather shelter’, to the water and electric network with materials that could resist the extreme conditions that being next to the sea could provide. The venue should have been suitable for weddings and other gatherings and equipped with catering facilities and restrooms.

Solution

Walraven’s expert advice is to use A4 stainless steel products to enhance durability, addressing the challenges posed by the salty and corrosive marine environment. Pressure drainage systems, cables, water pipes, and empty conduits, supplying the hut with essential utilities, will be fixed under the walkway to conceal the installations and ensure a clean and attractive aesthetic.

Due to the special requirements – including the salty, highly corrosive environment and wave action – only A4 stainless steel products were used for fastening under the walkway. Thermal length changes in the pipes due to extreme temperature differences and the length of the pier also had to be considered.

Beyond providing material solutions, Walraven offered comprehensive technical services, including load and expansion calculations for the pressure drainage system and detailed drawings for various fastening configurations.

Walraven utilised RapidStrut® mounting rails, support clamps, heavy-duty clamps, plain bearings, and other mounting accessories from their stainless steel product range to ensure a safe and long-lasting installation. All necessary materials were delivered directly to the construction site.

Contact our experts

The post How to create a sea resistant fastening systems? appeared first on Walraven International.

]]>The post “Sound without vibrations” – Walraven vibration isolators at the Academy of Music appeared first on Walraven International.

]]> Academy de music

Academy de music

Bydgoszcz I Poland

A new campus of the Academy of Music is being built in Bydgoszcz, a city in Poland. The academy was founded in 1974. Walraven has been involved in the project from the very beginning, from the moment the new academy building was designed in 2017.

For this investment, we work closely with the foremost installers on the construction site and support the main contractor from the installation perspective. Walraven is an expert in suspensions, and particularly in vibration isolation suspensions.

Challenge

The new campus of the Academy of Music consists of seven floors above ground and two floors underground. The Academy of Music is a place where any vibrations of installations and noises are highly undesirable. In buildings of this type, vibration isolation is crucial to ensure the comfort of use for students, musicians, guests, and the audience during concerts.

The very high density of installations on underground floors is a real challenge for installers, who must build their installation according to the building’s design, the music room’s specificities, and guidelines for vibration damping.

Walraven also dealt with the presence of dual-function channels, which is interesting because they have two types of suspensions at the same time: fire protection and vibration isolation. This set-up is unusual and increases the density of fastenings, which leads to a much complex installation than usual.

Solution

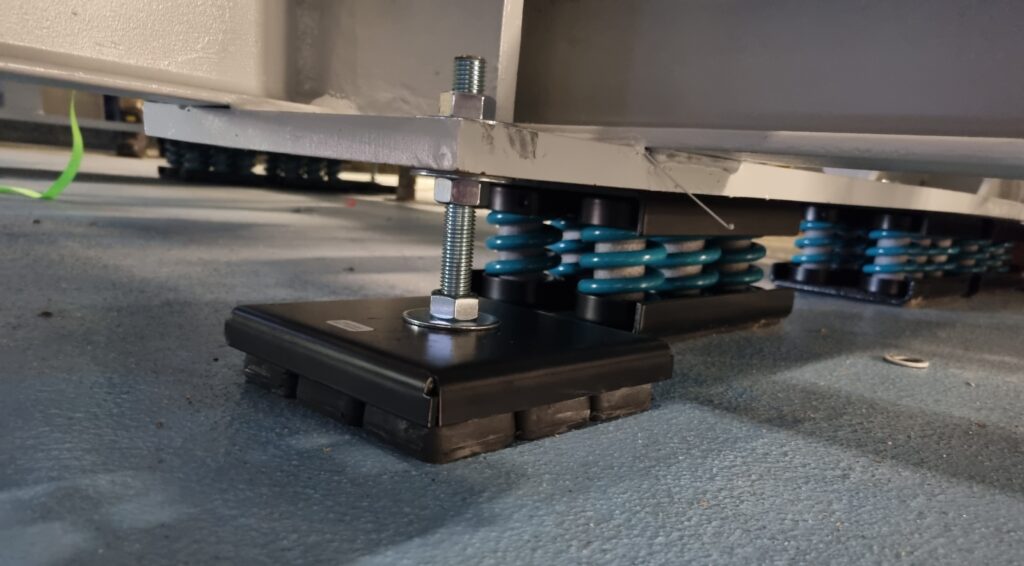

To achieve this complex installation, our Walraven VibraTek® solution was used to isolate the sanitary pipe system, and the fans and a fire protection system were also installed.

Vibration isolation throughout the entire facility is achieved using Walraven VibraTek® vibration isolators. This is the largest number of Walraven VibraTek® isolators used in one place in history!

The versatility and modularity of our solutions enable us to combine them in order to create the perfect solution for your project.

For noise isolation, our experts use the Walraven VibraTek® isolator, in combination with the Walraven RapidStrut® medium application fixing system to fix the pipe system and our Walraven WDI1 mechanical anchors to secure it to the ceiling.

The post “Sound without vibrations” – Walraven vibration isolators at the Academy of Music appeared first on Walraven International.

]]>The post RLT – Air handling and cooling systems safely installed on flat roofs appeared first on Walraven International.

]]>

Görlitz I Germany

Roof cladding-friendly, wind and snow load-resistant air handling and recooling systems on the flat roof of the Senckenberg Museum of Natural History Görlitz.

Massive systems were installed on stilts on the Museum of Natural History’s flat roof, including three air handling units weighing up to seven tonnes and three heat exchangers, each weighing three tonnes. In addition, the responsible parties planned the substructures for ventilation ducts and piping and installed convenient access points for maintenance work. They included stairs and crossings at the intersection points of the inspection routes to ensure safe and convenient access.

In addition, the roofer required more space under the units for roof inspections in subsequent years in accordance with DIN 18531-1. The long-term compressive strength of the roof insulation, considering the units’ weight, construction and ballast weight, snow load according to DIN EN 1991-1-3 and wind load according to DIN EN 1991-1-4 had to be ensured.

Optimum load distribution using Walraven Yeti® mounting feet and mounting rail constructions

Because of these requirements, the Walraven team led by Andreas Strobel, Regional Sales Manager for Project Business in Saxony, opted for the flexible Walraven Yeti® mounting feet. Together with Walraven Maxx mounting profiles for heavy-duty applications and RapidStrut® mounting rail constructions, they ensure optimal load distribution of the systems. ‘For large and heavy installations, roof loading plays a vital role. The optimised load distribution properties of the Walraven Yeti® mounting feet reduce point loads. The flexibility of the mounting rail design also allows the Yeti® feet to be arranged, taking roof inlets into account, explains Strobel.

Safe maintenance access on flat roofs: convenient, reliable and compliant with standards

Elevated maintenance platforms with secure gratings and stair elements enable easy access to the technology and guarantee simple and safe maintenance. ‘The access points to the maintenance elements of flat-roof installations must meet certain standards, such as DIN EN 14122-2. They should be easy to walk on without risk of injury,’ says Strobel.

Elevated maintenance platforms with secure gratings and stair elements enable easy access to the technology and guarantee simple and safe maintenance. ‘The access points to the maintenance elements of flat-roof installations must meet certain standards, such as DIN EN 14122-2. They should be easy to walk on without risk of injury,’ says Strobel.

Technical support

For lasting, reliable stability, Walraven experts provided support with snow and wind load calculations and appropriate ballasting recommendations. They also took on the design and dimensioning of the entire pipe support technology inside the building. They must meet specific standards, such as DIN EN 14122-2. They should be easy to walk on without risk of injury,’ says Strobel.

Do you have a question? Contact our expert!

The post RLT – Air handling and cooling systems safely installed on flat roofs appeared first on Walraven International.

]]>The post Effective vibration isolation techniques for a 14-ton machine appeared first on Walraven International.

]]>

For our client, a company specialising in implementing installation solutions for industrial and production facilities, we prepared a vibration isolation solution for an ammonia compressor with an operating weight of 14 tons.

The challenge

To achieve the best level of vibration isolation, around 98%, spring-based solutions with a deflection value of up to 20mm must be used. As the unit’s centre of mass is not its geometric centre, calculations had to be made to determine the loads from all 6 fixing points, allowing a different spring to be selected for each.

Solution

The rationale for using spring vibration isolation under equipment having large vibrating masses (e.g. pumps, fans, combustion engines) is:

- reduction of wear and tear on the equipment by improving its operating conditions

- no transmission of vibrations to the building structure and adjacent installations and equipment

- total reduction in wear and tear of the equipment’s anchoring to the floor or structure

The solution prepared assumed special 6-spring packages designed and prepared individually for this case.

Due to the slenderness of the unit and the high suspended centre of mass, it was necessary, in addition to the spring vibration isolation, to use additional EPDM vibration isolators – which do not carry the weight of the unit but compensate for the deflection of the unit, standard to a spring-based foundation.

The post Effective vibration isolation techniques for a 14-ton machine appeared first on Walraven International.

]]>The post How to install solar thermal tube collectors on pitched flat roofs without penetrating the roof cladding? appeared first on Walraven International.

]]>

Residential building

Altenburg I Germany

Introduction

In the historic town of Altenburg, Germany, known for its rich history and the invention of the card game Skat, a residential building required the installation of solar thermal tube collectors on its flat roof. The project was undertaken in collaboration with Walraven Group, with Andreas Strobel and Thomas Geissler leading the planning and execution phases. The primary challenge was installing the collectors without penetrating the roof cladding while compensating for the roof’s pitch.

Challenges

The client approached Walraven Group due to the complexity of the installation. The roof had a seven-degree pitch, and ensuring that the structure was positioned precisely on the load-bearing roof ribs was crucial. Additionally, the installation needed to minimise wind exposure and accommodate sufficient ballast without projecting too far over the roof edge.

Solution – How Did We Meet the Challenge?

Walraven Group provides comprehensive technical consulting and planning services. The solution involved using the Walraven Yeti® 480 mounting feet, which can compensate for roof pitches up to seven degrees and support compressive loads up to 20,000 newtons. This system ensured that the roof cladding remained intact and the load was optimally distributed.

- Technical Services Used: Engineering, structural calculations, and on-site consulting.

- Product Used: Walraven Yeti® 480 system for flexibility and load-bearing capacity.

- Organisation: The project involved precise planning to ensure the structure’s height and positioning met all specifications, with support from a structural engineer.

The system’s components, including the Walraven BIS UltraProtect®1000 surface protection, provided increased corrosion protection and durability. The injection-moulded parts, made from recycled materials, were weather—and UV-resistant, allowing easy installation and dismantling without damaging the building fabric.

Additional Technical Details:

- Sound Reduction: The SG-Bauakustik Institute determined the impact of sound reduction in accordance with DIN EN ISO 10140-1 and DIN EN ISO 10140-3, certifying a sound reduction of up to 31 dB(A).

- Load Distribution: The mounting system was designed to withstand local wind and snow loads, ensuring stability and safety under various environmental conditions.

- Modular Design: The modular system’s components can be easily extended as required, making it future-proof and adaptable to different project needs.

Andreas Strobel, Walraven project manager, provided comprehensive advice on-site and in numerous preliminary discussions. The Walraven application engineering colleagues provided support with technical designs in the form of drawings, parts lists, and preliminary structural calculations.

Learn more about our Walraven Rooftop Solutions and Walraven Solar Panels Solutions

The post How to install solar thermal tube collectors on pitched flat roofs without penetrating the roof cladding? appeared first on Walraven International.

]]>The post Omefa: Optimising logistics processes appeared first on Walraven International.

]]>

Background

Efficiency is a crucial element in manufacturing and logistics. Companies continuously seek ways to enhance and streamline their processes to remain competitive in a rapidly changing market. Omefa, a leading company that processes plastic pellets into high-quality products, recently expanded its facilities by adding a new materials department to improve its logistics processes. This addition integrates seamlessly with the existing infrastructure, allowing Omefa to increase production capacity while enhancing the efficiency of its logistics.

Requirement

Omefa approached Walraven to develop a horizontal and vertical pipe-fixing network that would fit into the new part of the building and facilitate the relocation of silos without disrupting the efficient material flow. Indeed, one side of the building is dedicated to raw materials, which undergo various processes before being transformed into finished products on the opposite side.

Omefa approached Walraven to develop a horizontal and vertical pipe-fixing network that would fit into the new part of the building and facilitate the relocation of silos without disrupting the efficient material flow. Indeed, one side of the building is dedicated to raw materials, which undergo various processes before being transformed into finished products on the opposite side.

As a quality specialist in innovative pipework solutions, Walraven was asked to provide the fixing system for the internal section of the warehouse, ensuring that the installation was modular to accommodate future organisational changes. The piping system needed to align with the suction system that would take the raw plastic pellets from one side of the factory and route them to the different stages of production.

Additionally, Walraven designed a rooftop support solution that allowed access to certain roof parts without causing damage.

Solutions

Walraven’s RapidStrut® system and KSB2 brackets created a flexible and user-friendly mounting grid in the warehouse. Thanks to the Walraven RapidStrut system accessories, the installation could have been quickly assembled and, if necessary, dissembled in the future, allowing adaptability if Omefa’s production processes change.

The pipe system extends beyond the interior, reaching the roof, where Walraven designed various mounting systems on different staircases. These custom solutions ensure safe and easy access to rooftop sections. Additionally, the Walraven Yeti® feet provide stability on flat roofs without causing damage from drilling.

If you’re facing a similar challenge or need advice on a different issue, contact our technical support team

The post Omefa: Optimising logistics processes appeared first on Walraven International.

]]>