The characteristics:

- Weight: light – heavy

- Disturbing frequency: low – medium

- Mounting: standing

Find below our tables of Damping efficiency upon disturbing frequency

Walraven VibraTek® selection matrix:

How to evaluate the suitability of an isolator?

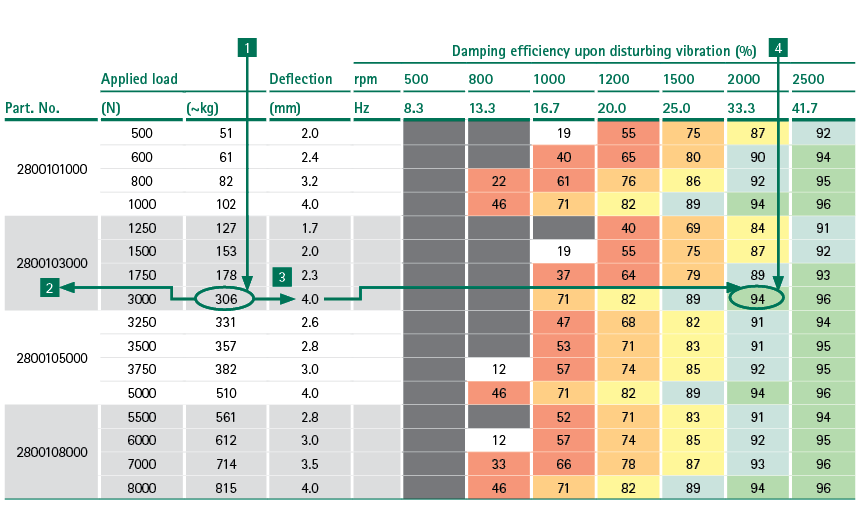

How to read the tables?

Example: the load per one vibro-isolator is 280 kg, and the operating frequency of the device is 2300 rpm. See the 5 steps to read from the table (as shown in the attached diagram) to find out if the selected vibro-isolator meets the damping conditions and is well-matched.

The motor’s speed (rpm) causes vibrations (Hz) in HVAC devices. To simplify product selection, we’ve organized tables by speed, as it’s easily obtainable from suppliers

- Select the weight of the device in the table – greater than or equal to 280 kg

- Horizontally to the left, you can see the product number of Walraven VibraTek®

- Horizontally to the right, you can read the deflection

- Locate the column with a frequency lower than 2300 rpm

- Read the damping performance at: cross-deflection and frequency

Damping efficiency upon disturbing frequency

Damping performance description

| V[%] | Damping performance description | |||

| 99% | excellent | high requirements | medium requirements | regular requirements |

| 93% | perfect | |||

| 88% | very good | |||

| 81% | good | |||

| 67% | sufficient | |||

| 20% | mediocre | low improvement or negative impact – contact Walraven Technical Support for alternative solution | ||

| 0% | nochange | |||

| resonance | better without insulation | |||

Walraven VibraTek® MS-1

| Walraven VibraTek® MS-1 |

Damping efficiency upon disturbing frequency | ||||||||||

| Article no.: | load on vibroisolator | deflection | RPM | 500 | 800 | 1000 | 1200 | 1500 | 2000 | 2500 | |

| [N] | [~kg] | [mm] | Hz | 8,3 | 13,3 | 16,7 | 20,0 | 25,0 | 33,3 | 41,7 | |

| 2800300050 | 25 | 2,5 | 11,5 | 54,6% | 86,1% | 91,5% | 94,3% | 96,4% | 98,0% | 98,7% | |

| 50 | 5 | 23,0 | 81,5% | 93,5% | 95,9% | >97,2% | 98,2% | 99,0% | 99,4% | ||

| 2800300150 | 100 | 10 | 15,3 | 69,4% | 89,9% | 93,8% | 95,8% | 97,3% | 98,5% | 99,1% | |

| 150 | 15 | 23,0 | 81,5% | 93,5% | 95,9% | 97,2% | 98,2% | 99,0% | 99,4% | ||

| 2800300250 | 200 | 20 | 18,4 | 75,8% | 91,7% | 94,9% | 96,5% | 97,8% | 98,8% | 99,2% | |

| 250 | 25 | 23,0 | 81,5% | 93,5% | 95,9% | 97,2% | 98,2% | 99,0% | 99,4% | ||

| 2800300500 | 300 | 30 | 13,8 | 64,8% | 88,7% | 93,0% | 95,3% | 97,0% | 98,3% | 98,9% | |

| 400 | 40 | 18,4 | 75,8% | 91,7% | 94,9% | 96,5% | 97,8% | 98,8% | 99,2% | ||

| 500 | 50 | 23,0 | 81,5% | 93,5% | 95,9% | 97,2% | 98,2% | 99,0% | 99,4% | ||

| 2800300750 | 600 | 60 | 18,4 | 75,8% | 91,7% | 94,9% | 96,5% | 97,8% | 98,8% | 99,2% | |

| 750 | 75 | 23,0 | 81,5% | 93,5% | 95,9% | 97,2% | 98,2% | 99,0% | 99,4% | ||

| 2800301000 | 800 | 80 | 18,4 | 75,8% | 91,7% | 94,9% | 96,5% | 97,8% | 98,8% | 99,2% | |

| 900 | 90 | 20,7 | 79,0% | 92,7% | 95,5% | 96,9% | 98,0% | 98,9% | 99,3% | ||

| 1000 | 100 | 23,0 | 81,5% | 93,5% | 95,9% | 97,2% | 98,2% | 99,0% | 99,4% | ||

Walraven VibraTek® MS-1X

| Walraven VibraTek® MS-1X |

Damping efficiency upon disturbing frequency | ||||||||||

| Article no.: | load on vibroisolator | deflection | RPM | 500 | 800 | 1000 | 1200 | 1500 | 2000 | 2500 | |

| [N] | [~kg] | [mm] | Hz | 8,3 | 13,3 | 16,7 | 20,0 | 25,0 | 33,3 | 41,7 | |

| 2800401250 | 1100 | 110 | 22,0 | 80,5% | 93,2% | 95,7% | 97,1% | 98,2% | 99,0% | 99,3% | |

| 1500 | 125 | 25,0 | 83,2% | 94,1% | 96,3% | 97,4% | 98,4% | 99,1% | 99,4% | ||

| 2800401500 | 1400 | 140 | 23,3 | 81,8% | 93,6% | 96,0% | 97,3% | 98,3% | 99,0% | 99,4% | |

| 1500 | 150 | 25,0 | 83,2% | 94,1% | 96,3% | 97,4% | 98,4% | 99,1% | 99,4% | ||

| 2800402000 | 1750 | 175 | 21,9 | 80,4% | 93,1% | 95,7% | 97,1% | 98,1% | 99,0% | 99,3% | |

| 2000 | 200 | 25,0 | 83,2% | 94,1% | 96,3% | 97,4% | 98,4% | 99,1% | 99,4% | ||

| 2800403000 | 2200 | 220 | 18,3 | 75,6% | 91,7% | 94,9% | 96,5% | 97,8% | 98,8% | 99,2% | |

| 2600 | 260 | 21,7 | 80,1% | 93,1% | 95,7% | 97,0% | 98,1% | 99,0% | 99,3% | ||

| 3000 | 300 | 25,0 | 83,2% | 94,1% | 96,3% | 97,4% | 98,4% | 99,1% | 99,4% | ||

| 2800404000 | 3500 | 350 | 21,9 | 80,4% | 93,1% | 95,7% | 97,1% | 98,1% | 99,0% | 99,3% | |

| 4000 | 400 | 25,0 | 83,2% | 94,1% | 96,3% | 97,4% | 98,4% | 99,1% | 99,4% | ||

| 2800405000 | 4300 | 430 | 21,5 | 80,0% | 93,0% | 95,6% | 97,0% | 98,1% | 98,9% | 99,3% | |

| 4600 | 460 | 23,0 | 81,5% | 93,5% | 95,9% | 97,2% | 98,2% | 99,0% | 99,4% | ||

| 5000 | 500 | 25,0 | 83,2% | 94,1% | 96,3% | 97,4% | 98,4% | 99,1% | 99,4% | ||

| 2800406000 | 5300 | 530 | 22,1 | 80,6% | 93,2% | 95,8% | 97,1% | 98,2% | 99,0% | 99,3% | |

| 5600 | 560 | 23,3 | 81,8% | 93,6% | 96,0% | 97,3% | 98,3% | 99,0% | 99,4% | ||

| 6000 | 600 | 25,0 | 83,2% | 94,1% | 96,3% | 97,4% | 98,4% | 99,1% | 99,4% | ||

Walraven VibraTek® MS-1X-CBL

| Walraven VibraTek® MS-1X-CBL | Damping efficiency upon disturbing frequency | ||||||||||

| Article no.: | load on vibroisolator | deflection | RPM | 500 | 800 | 1000 | 1200 | 1500 | 2000 | 2500 | |

| [N] | [~kg] | [mm] | Hz | 8,3 | 13,3 | 16,7 | 20,0 | 25,0 | 33,3 | 41,7 | |

| 2801901000 | 800 | 80 | 20,0 | 78,1% | 92,5% | 95,3% | 96,8% | 98,0% | 98,9% | 99,3% | |

| 1000 | 100 | 25,0 | 83,2% | 94,1% | 96,3% | 97,4% | 98,4% | 99,1% | 99,4% | ||

| 2801901250 | 1100 | 110 | 22,0 | 80,5% | 93,2% | 95,7% | 97,1% | 98,2% | 99,0% | 99,3% | |

| 1250 | 125 | 25,0 | 83,2% | 94,1% | 96,3% | 97,4% | 98,4% | 99,1% | 99,4% | ||

| 2801901500 | 1400 | 140 | 23,3 | 81,8% | 93,6% | 96,0% | 97,3% | 98,3% | 99,0% | 99,4% | |

| 1500 | 150 | 25,0 | 83,2% | 94,1% | 96,3% | 97,4% | 98,4% | 99,1% | 99,4% | ||

| 2801902000 | 1750 | 175 | 21,9 | 80,4% | 93,1% | 95,7% | 97,1% | 98,1% | 99,0% | 99,3% | |

| 2000 | 200 | 25,0 | 83,2% | 94,1% | 96,3% | 97,4% | 98,4% | 99,1% | 99,4% | ||

| 2801903000 | 2200 | 220 | 18,3 | 75,6% | 91,7% | 94,9% | 96,5% | 97,8% | 98,8% | 99,2% | |

| 2600 | 260 | 21,7 | 80,1% | 93,1% | 95,7% | 97,0% | 98,1% | 99,0% | 99,3% | ||

| 3000 | 300 | 25,0 | 83,2% | 94,1% | 96,3% | 97,4% | 98,4% | 99,1% | 99,4% | ||

| 2801904000 | 3500 | 350 | 21,9 | 80,4% | 93,1% | 95,7% | 97,1% | 98,1% | 99,0% | 99,3% | |

| 4000 | 400 | 25,0 | 83,2% | 94,1% | 96,3% | 97,4% | 98,4% | 99,1% | 99,4% | ||

| 2801905000 | 4300 | 430 | 21,5 | 80,0% | 93,0% | 95,6% | 97,0% | 98,1% | 98,9% | 99,3% | |

| 4600 | 460 | 23,0 | 81,5% | 93,5% | 95,9% | 97,2% | 98,2% | 99,0% | 99,4% | ||

| 5000 | 500 | 25,0 | 83,2% | 94,1% | 96,3% | 97,4% | 98,4% | 99,1% | 99,4% | ||

| 2801906000 | 5300 | 530 | 22,1 | 80,6% | 93,2% | 95,8% | 97,1% | 98,2% | 99,0% | 99,3% | |

| 5600 | 560 | 23,3 | 81,8% | 93,6% | 96,0% | 97,3% | 98,3% | 99,0% | 99,4% | ||

| 6000 | 600 | 25,0 | 83,2% | 94,1% | 96,3% | 97,4% | 98,4% | 99,1% | 99,4% | ||

Walraven VibraTek® MR-B

| Walraven VibraTek® MR-B | Damping efficiency upon disturbing frequency | ||||||||||

| Article no.: | load on vibroisolator | deflection | RPM | 500 | 800 | 1000 | 1200 | 1500 | 2000 | 2500 | |

| [N] | [~kg] | [mm] | Hz | 8,3 | 13,3 | 16,7 | 20,0 | 25,0 | 33,3 | 41,7 | |

| 2801800240 | 200 | 20 | 2,9 | 633,0% | 7,4% | 55,5% | 72,8% | 84,2% | 91,7% | 94,8% | |

| 240 | 24 | 3,5 | 4077,4% | 33,1% | 65,5% | 78,3% | 87,1% | 93,1% | 95,7% | ||

| 2801800750 | 450 | 45 | 2,4 | 401,6% | -40,6% | 40,3% | 64,9% | 80,1% | 89,7% | 93,6% | |

| 750 | 75 | 4,0 | -776,2% | 46,0% | 71,1% | 81,5% | 88,9% | 94,1% | 96,3% | ||

| 2801801500 | 1000 | 100 | 3,7 | -4599,3% | 38,1% | 67,6% | 79,5% | 87,8% | 93,5% | 95,9% | |

| 1500 | 150 | 5,5 | -88,0% | 65,8% | 80,5% | 87,2% | 92,2% | 95,7% | 97,3% | ||

Walraven VibraTek® MR-L

| Walraven VibraTek® MR-L | Damping efficiency upon disturbing frequency | ||||||||||

| Article no.: | load on vibroisolator | deflection | RPM | 500 | 800 | 1000 | 1200 | 1500 | 2000 | 2500 | |

| [N] | [~kg] | [mm] | Hz | 8,3 | 13,3 | 16,7 | 20,0 | 25,0 | 33,3 | 41,7 | |

| 2800101000 | 500 | 50 | 2,0 | 326% | -135% | 19% | 55% | 75% | 87% | 92% | |

| 600 | 60 | 2,4 | 402% | -41% | 40% | 65% | 80% | 90% | 94% | ||

| 800 | 80 | 3,2 | 1020% | 22% | 61% | 76% | 86% | 92% | 95% | ||

| 1000 | 100 | 4,0 | -776% | 46% | 71% | 82% | 89% | 94% | 96% | ||

| 2800103000 | 1250 | 125 | 1,7 | 287% | -431% | -17% | 40% | 69% | 84% | 91% | |

| 1500 | 150 | 2,0 | 326% | -135% | 19% | 55% | 75% | 87% | 92% | ||

| 1750 | 175 | 2,3 | 386% | -51% | 37% | 64% | 79% | 89% | 93% | ||

| 3000 | 300 | 4,0 | -776% | 46% | 71% | 82% | 89% | 94% | 96% | ||

| 2800105000 | 3250 | 325 | 2,6 | 463% | -17% | 47% | 68% | 82% | 91% | 94% | |

| 3500 | 350 | 2,8 | 554% | 0% | 53% | 71% | 83% | 91% | 95% | ||

| 3750 | 375 | 3,0 | 708% | 12% | 57% | 74% | 85% | 92% | 95% | ||

| 5000 | 500 | 4,0 | -776% | 46% | 71% | 82% | 89% | 94% | 96% | ||

| 2800108000 | 5500 | 550 | 2,8 | 527% | -4% | 52% | 71% | 83% | 91% | 94% | |

| 6000 | 600 | 3,0 | 708% | 12% | 57% | 74% | 85% | 92% | 95% | ||

| 7000 | 700 | 3,5 | 4077% | 33% | 66% | 78% | 87% | 93% | 96% | ||

| 8000 | 800 | 4,0 | -776% | 46% | 71% | 82% | 89% | 94% | 96% | ||