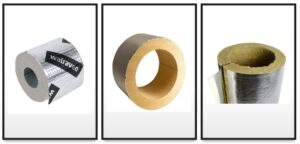

Insulated pipe support inserts (sometimes referred to as ‘blocks’) fit around a pipe where the pipe clamps are positioned, to both insulate and provide load bearing support. The inserts prevent contact between the pipe and the clamp which can lead to heat loss and condensation. They also provide a vapour barrier against moisture which can protect pipes from corrosion.

Insulated pipe support inserts (sometimes referred to as ‘blocks’) fit around a pipe where the pipe clamps are positioned, to both insulate and provide load bearing support. The inserts prevent contact between the pipe and the clamp which can lead to heat loss and condensation. They also provide a vapour barrier against moisture which can protect pipes from corrosion.

Traditionally insulation blocks are used on chilled water applications to help ensure a continuous run of insulation, where a complete vapour barrier is key to system integrity. However, they are also now increasingly used for other HVAC services since the changes to BS 5970:2012 recognised the energy-saving benefits of using insulated pipe supports on above ambient services.

Whilst pipe supports only come into contact with a small area of a total service run, if they are not insulated effectively, these points can account for a significant proportion of heat loss from above ambient temperature systems. This can undermine other measures put in place to improve energy efficiency.

In days gone by, hardwood blocks were the only option available. But thanks to new technologies and new product developments, there are now a number of alternatives which offer significantly superior thermal performance than wood blocks.

In days gone by, hardwood blocks were the only option available. But thanks to new technologies and new product developments, there are now a number of alternatives which offer significantly superior thermal performance than wood blocks.

The main types of insulation block currently available are:

Despite their poor insulation properties, susceptibility to condensation and lack of fire resistance, wood blocks are still on the market, although their usage has declined significantly. The British Standard for insulated pipe supports, BS5970:2012, was updated to give the view that “wooden pipe supports should not be used” given their poor insulation properties.

Phenolic block offers one of the best all round solutions currently available, and is often the preferred choice. They are cost-effective, versatile and extremely thermally efficient. Phenolic blocks offer high levels of thermal insulation, an effective vapour and condensation barrier and a fire resistance level which means they have very low combustibility.

Mineral wool blocks are fairly new to the market. Their main benefit is for high temperature systems as they are non-combustible. So they would offer a good solution for very high temperature environments like power plants, refineries and chemical plants. Their overall thermal performance is not as robust as phenolic so they can be an expensive solution for chilled water and low temperature systems where phenolic provides a more all-round, cost-effective option.

Calcium silicate is another high temperature solution for those more specialist environments where temperatures exceed 120°C. It also has a high compressive strength. Therefore, it is an option best placed for more specialist environments.

For a more detailed comparison of phenolic, wood and mineral wool blocks, you can read our blog on the topic.

Generally it is not recommended to use wood blocks any longer unless there is a specific reason to, because the alternatives offer much superior performance. Ultimately, the choice depends on several factors including:

As mentioned, phenolic pipe insulation is a great all-rounder for chilled and low temperature systems and mineral wool has advantages for high temperature situations.

There are two British Standards that are relevant for insulated pipe supports.

BS5970 gives the recommendation that load bearing insulated pipe supports should be used on chilled water and low temperature installations. It also states that “wooden pipe supports should not be used” any longer because of their poor performance regarding insulation and vapour barrier which is essentially the primary function of the pipe support. This standard has paved the way for superior products to be used such as phenolic blocks and mineral wool to make constructions more thermally efficient on the drive to net zero.

Installing the correct thickness of insulation around building services is essential to ensure they perform as expected. BS5422 gives minimum or indicative insulation thicknesses for different applications. This is an important consideration because the thermal performance of different insulation products varies. For example, phenolic insulated pipe supports offer higher thermal insulation levels than mineral wool blocks, so each type of product would require a different thickness to deliver the same level of insulation.

Walraven Phenblox® are UK-made phenolic load-bearing pipe supports for steel, copper and plastic pipes. They are manufactured from high density phenolic foam in accordance with BS EN 14314:2015. Here are some of their main characteristics:

Walraven Phenblox® are UK-made phenolic load-bearing pipe supports for steel, copper and plastic pipes. They are manufactured from high density phenolic foam in accordance with BS EN 14314:2015. Here are some of their main characteristics:

*This is the highest performance achievable for phenolic foam blocks and means very limited contribution to fire, little or no smoke emissions and no burning droplets. The European Phenolic Foam Association (EPFA) gives an overview of the properties of phenolic foam.

View our product page for Walraven Phenblox® where you can find all the technical information about our phenolic.

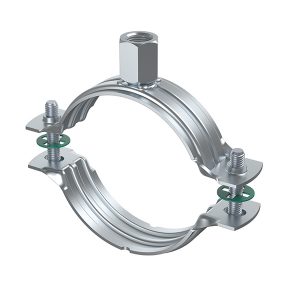

Alongside Walraven Phenblox® we can offer a variety of Walraven pipe clamps to secure the insulated pipe supports in place, including our standard 2S clamps, HD Heavy Duty clamps and split bands. We have load bearing data available for our Phenolic block/2S clip combination if required, for added peace of mind. Whichever type of clamp you choose, our handy phenolic and clamp selection chart helps you choose the right combination of block and clip.

Alongside Walraven Phenblox® we can offer a variety of Walraven pipe clamps to secure the insulated pipe supports in place, including our standard 2S clamps, HD Heavy Duty clamps and split bands. We have load bearing data available for our Phenolic block/2S clip combination if required, for added peace of mind. Whichever type of clamp you choose, our handy phenolic and clamp selection chart helps you choose the right combination of block and clip.

As well as manufacturing phenolic insulation blocks, we also provide all of the individual components that, when used together, create the complete pipe support system. This includes parts such as:

Our Projects and Technical Support Team can provide advice and designs should you require assistance in selecting the right combination of products for your installation.

Fill in the form to ask us a question and we will get in touch.